EDF select “Kyowa Filter Units” for monopile scour protection on Teesside OWF

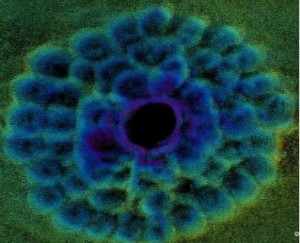

Ridgeway Renewables have successfully supplied the first “Kyowa Filter Units” from Japanese manufacturer Sumisho Kyowa Limited for offshore wind turbine monopile scour protection in Europe. Using a combination of the 4 & 8 tonne type units filled with specific aggregate in a circular formation around the monopile, engineers were able to achieve tough design criteria set for sea and wave conditions. Filter Units offer virtually-no-maintenance scour performance protection by having a flexible structure. They are easy, safe and fast to install and are made from 61% recycled water bottles and offer a natural eco habitat for marine life when installed.

Ridgeway worked closely with the developer EDF Energy and the consulting engineer Ramboll, who were responsible for the scour protection design. Following many meetings with the design engineers and the TOWF project management the green light was given to utilise the innovative solution for scour protection on 11 of the 27 turbines.

EDF Energy Renewables awarded specialist engineering and solutions company, Marske Site Services (MSS) the vital role of turnkey installation contractor for the placement of the Filter Units. From this point Ridgeway Renewables were sub-contracted to supply and fill the filter units at the Port of Sunderland. MSS utilised the 7000te subsea construction vessel, the Maersk Responder to safely and accurately place the scour protection in the Tees Bay. This represented a tremendous example of business collaboration and cooperation to move a project like this along at a pace faster than normally associated with the largest projects in this sector.

With a limited working window, Ridgeway along with their quarries and filling contractor mobilised on site within days at The Port of Sunderland, commencing the filling operation on 18th March and completing in exactly one month. During this time Ridgeway and MSS maintained and operated a strict health and safety protocol on site working to the arranged dates to complete the quantity of filter units required to follow the vessel installation schedule.

The MSS Engineering team mobilised the vessel, coming up with a unique solution for safely transporting an extra-large load of filter bags, which combined with a 50% improvement in the time taken to complete each monopile.

Stephen Kane, MD of Ridgeway Renewables, said “it took a significant

amount of team effort to make this project happen and we are particularly pleased that collectively all businesses came together to deliver the project ahead of schedule and to the satisfaction of our clients”.

John McCullagh, MD of MSS, also commented “Ridgeway and their friends from Japan have been great to work with. Together they’ve played a key role in establishing the benefits of this unique scour protection system over traditional rock dump and concrete methods into the market and have been instrumental in persuading the client and their design team to run with the system. They have proved their capability on the filling site in an efficient, safe and professional manner. We see a great future ahead for this product and the team now established”

On completion of the work EDF Energy Renewables Project Manager Tim Bland thanked the team at MSS for the “brilliantly executed job”.